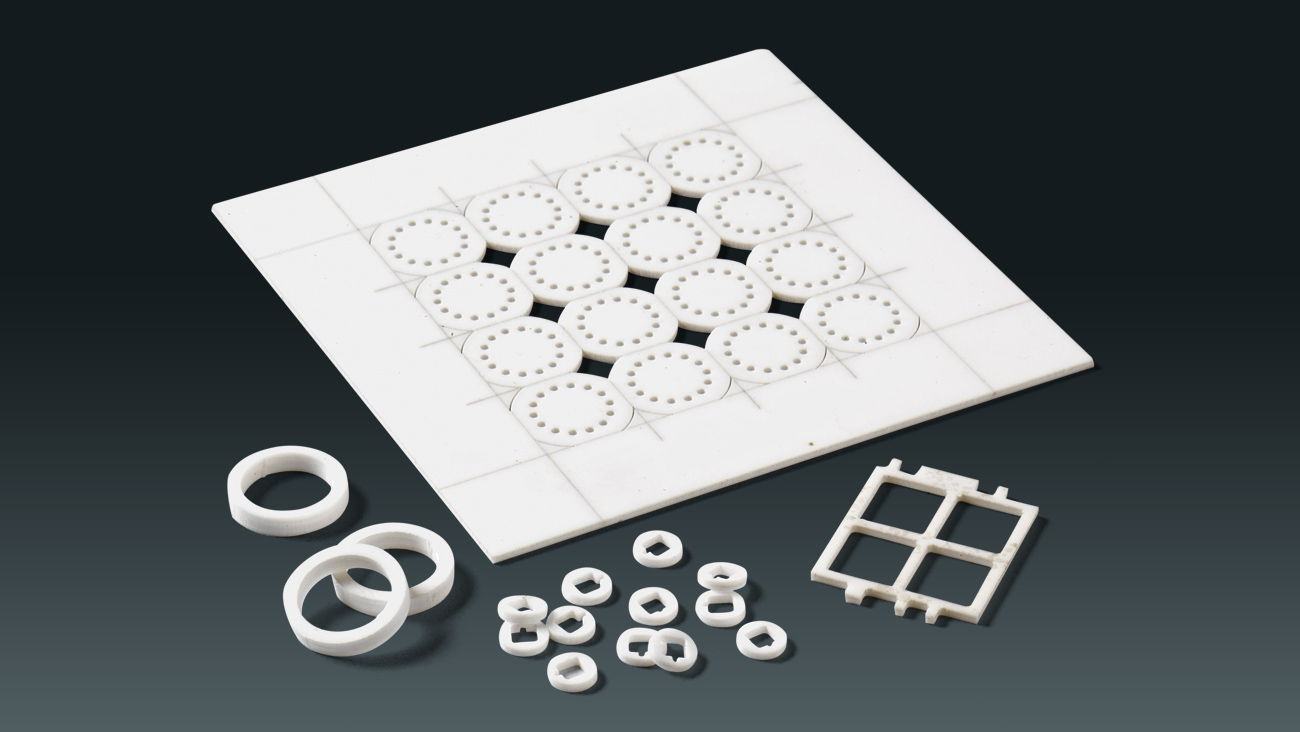

Low Volume, Quick Turn, Ceramic Substrates with Expert Laser Processing Critical in RF and Medical Supply Chains

We often engage in conversations with our RF and microelectronics and medical industries supply chain managers about their unique purchasing requirements for substrates and related advanced material processing needs. What we hear most often is that without smaller ceramic substrates stocking distributors like us who offer Toshiba, Kyocera, Coorstek, Corning, Ceramtech and Dynasil substrates with a full suite of processing and machining services, a critical component in these microelectronics manufacturers’ supply chains would be missing. While it's easy to maintain higher volume/bulk buys of non-processed ceramics, etc. with larger distributors, it's a challenge to address low volume, and quick-turn prototyping when fast processing and fast delivery is needed. That's where we come in. Our buying power allows us to offer very competitive pricing, flexible stocking plans, and full-service processing to customize delivery programs. We're one of the few advanced ceramic machining and precision lapping and polishing manufacturers who will hold your ceramic substrate inventory until it's needed. We guarantee that we can process, package, and deliver materials on a just-in-time basis.

So by stocking popular materials like alumina, aluminum nitride, tungsten carbide, fused silica and more, we can become a buyer's personal stockroom for the products needed just-in-time—and fully processed!

We stock ceramic substrates, metals, foils, epoxies, microwave absorbers, 3M medical adhesives, plastics, frozen epoxies, Kevlar, Teflon, and whatever other materials designers and procurement agents are looking for in a pinch. When customers want substrates fully cut, drilled, welded, scribed, etched or marked, we are the processing partner who stocks these materials and becomes an invaluable resource. Brand name suppliers and large distributors are the first sources of supply, their lead times and minimum orders can throw a monkey wrench into production plans when products need to get out the door quickly. Microcircuit manufacturers looking to reduce the cost, time, and materials needed to fabricate their microelectronic circuits thank us for being such a flexible ally. In addition to stocking all major brands of substrate material, we are experts at cutting, drilling, and scribing, as well as post-processing and ablation.

We also provide ultra-precise lapping, polishing, and diamond cutting of ferrous and non-ferrous metals and ceramic substrates, too. Lapping can be completed from 6 μin to 60 μin and polishing of materials is from 0.1 μin to 5 μin. Accumet can also scribe or dice rectangular or other odd-shaped parts up to 0.150” thick in geometries and as small as 0.005” x 0.005”. Accuracy can be held to +/-0.0003”; repeatability to within 0.0001”. Diamond machined edges/bevels and chamfers can be machined within 0.0005”.

To learn more, download our tech brief, "Selecting the Right Substrate Materials for High Power Electronics" and read more about why we are a recognized industry leader by Microwaves and RF.

Contact us today to set up your substrate materials stocking and processing plan.