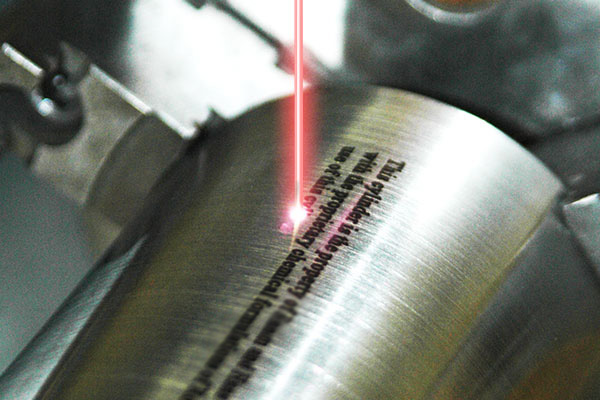

Laser Rotary Engraving of Bar Codes and Sequential Serial Numbers

If you’re looking to engrave a barcode, serial number, photograph, piece of artwork, a logo, or some decorative lettering onto a curved object, then laser rotary engraving is your best option. Mechanical rotary engraving methods such as diamond dragging, stamping or dot peening tend to be slower, require more setup time, and are more limited in the variety of patterns they can engrave. Lasers are also inherently more controllable — you just dial up or down the power of the laser to increase or decrease the depth of the marking. Greater control also makes lasers better suited for engraving delicate materials that might be destroyed by more aggressive mechanical methods. Lasers are also easier to program so their setup time is usually less and it’s easier to imprint marks like serial numbers that are incremented with each unit marked.

Despite all those advantages, however, there are still some applications where mechanical methods outshine lasers — especially for engraving certain materials. Not all plastics are laserable, for example, since some (like those with PVCs) will give off toxic fumes when vaporized. Rocks with highly contrasting color bands — some granite, for example — are another case where mechanical engraving may have an edge.

Diamond engraving is also known for its attractive V-shaped cut, which is an alternative to the straight vertical cut achieved when using a laser. (Diamond engraving can do vertical cuts, as well.) On the other hand, if the objective is to engrave a more complex marking such as a photograph, decorate typeface, or logo, then laser may be the only practical alternative. A laser can mark almost any pattern that can be imaged with light — since obviously a laser is light.

Given all its advantages, the laser option is always worth a look. Even an application that you’ve already been told is impossible may in fact be possible with a laser — or, at least, with our lasers. That’s because we have made special proprietary modifications to both our processes and to our equipment that enable us to go beyond what even competitive laser service providers can accomplish. We will even sample your job at no cost or obligation if you send us your requirements along with some of the objects to be engraved.

To learn more, download our tech brief, "The Speed and Precision of Laser Etching vs. Mechanical Engraving."